Suitable for packing liquid material in the pharmacy(medicine),food,daily chemical and other industries, automatic packing into sachet with Measurement requirement,such as milk, water, juice,ice lolly,soy sauce, vinegar, wine, medicine (water), chemical agent (water) and much more.

The Back Seal Honey Pouch Packaging Machine has strong adaptability to packaging materials and can adapt to a variety of packaging films produced at home and abroad. The packaging parameters can be adjusted through the touch screen, and multiple sets of parameters can be stored to improve work efficiency.

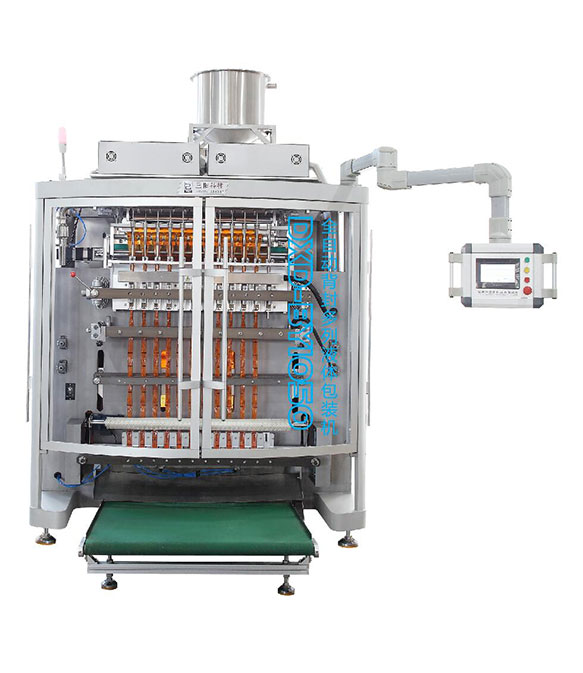

1. This automatic packaging machine can automatically complete the functions of automatic metering, automatic filling, automatic bag making (printing), sealing, fixed bag cutting, etc. of multiple columns of products without excessive manual intervention, which greatly improves production efficiency.

During the filling process, through the precise metering system, it can ensure that the amount of liquid in each pouch is accurate and meets the product requirements.

2. Automatic fault alarm, automatic shutdown, self-diagnosis, simple to use, quick maintenance, automatic display of packaging quantity, convenient machine workload statistics, and automatic shutdown function can protect the equipment from further damage while reducing the downtime of the production line.

3. Adopting the heat sealing working principle, the motor controls the film pulling, the bag pulling is fast and stable, and the motor-controlled film pulling system can ensure that the bag pulling process is fast and stable, reducing the deformation and damage of the bag during the film pulling process.

4. The high-sensitivity photoelectric induction switch can automatically track and locate the printing cursor, and a complete trademark pattern can be obtained when packaging materials with color codes.

5. The integrated support frame is used, which is more convenient to adjust. The whole machine is made of 304 stainless steel and aluminum alloy, which is corrosion-resistant and easy to clean. It meets GMP standards and ensures the hygiene and safety of the product during the production process.

|

Model |

DXD-BY1080 |

||

|

Lanes number |

8-16 lanes |

||

|

Packing material |

Liquid |

||

|

Packing speed |

40-50 bags/min/lane(according to filling material) |

||

|

Filling capacity |

1-50gram/bag |

||

|

Packing film |

PET/AL/PE、PET/PE、NY/AL/PE、NY/PE etc |

||

|

Bag size |

L:40-160mm adjustable |

||

|

|

|||

|

Film width |

Max.1080mm |

||

|

Sealing type |

Back sealing stick type bag |

||

|

Power supply |

380V,3PW, 50HZ(do as customer’s request) |

||

|

Power |

15-25KW |

||

|

Air consumption |

0.8MPA 0.8m3/min |

||

|

Dimension(mm) |

2900X2500X3500 |

||

|

Weight |

3000KG |

||