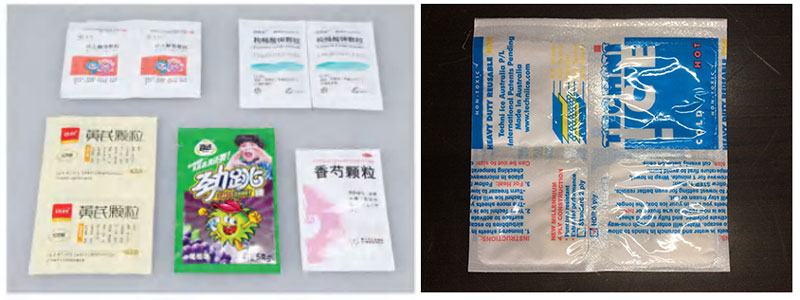

Granule Multi-layer Pouch Vertical 4 Side Sealing Machine is suitable for packing loose, non sticky granule material in the medicine, food, daily chemical and other industry, and automatically packing materials into sachets with measuring requirement.

Such as Chinese medicine infusion, oatmeal, coffee etc. Crystalline materials as monosodium glutamate, white sugar, salt etc. Small shot materials as Chinese patent drug, dryer and so on.

1. Advanced performance, high strength, low noise, compact structure, smooth operation and long service life. A film splicing mechanism has been added to make film replacement and maintenance more convenient.

2. It adopts five-axis servo synchronous drive, touch adjustment on the human-machine interface, and PLC control to enable precise and automatic synchronous positioning of each actuator. The packaging quality is guaranteed while increasing the packaging speed.

3. Use high-precision integral rolling heat sealing rollers to seal the four sides of the sealing mold. The bag-shaped flat seal is firm, delicate and beautiful, and the packaging quality is good and efficient.

4. Adjustment is quick and convenient. The bag length can be adjusted steplessly without changing the mold. And the actuators such as vertical sealing, horizontal sealing, filling material, batch number printing, dotted line cutting, and cross cutting can all be adjusted through the human-machine interface.

5. The use of a two-way synchronous feeding mechanism greatly increases the packaging speed. The mechanism adopts a detachable structure, which is simple to disassemble and assemble, and is easy to clean and maintain. Accurate filling and metering. DXDO-K900EM Granule Multi-layer Pouch Vertical 4 Side Sealing Machine is specially equipped with measuring cup with granule materials.

6. The photoelectric tracking system is adopted to ensure automatic alignment of the double-sided patterns of the packaging bag and has an automatic counting function.

7. This model is specially equipped with automatic film deflection correction and film yin mechanism to ensure the stability of the straightness and tension of the film, thereby greatly improving the smoothness and beauty of the bag shape.

8. It has strong adaptability to packaging materials. The sealing temperature of this machine has automatic control function and high control accuracy. It can be adapted to a variety of packaging films produced at home and abroad, such as PETAL/PE, PET/PE, NY/AL/PE, NY/PE, etc.

9. It can be adapted to add additional functions, such as bag cutting with optional dotted line knife, flat knife, and even heterosexual knife. And optional various alarm requirements, etc.

| Model | DXDO-K900EM |

| Pouch length | 50-150mm (adjustable) |

| Pouch width | 50-105mm |

| Packing speed | 30-60 times/min (depend by pouch size&material) |

| Filling capacity | 0.5-60ml |

| Applicable film | PET/AL/PE PET/PE NY/AL/PE NY/PE |

| Max film width | 450mm |

| Max film diameter | Φ 300mm |

| Film core diameter | Φ 75mm |

| Electric source | 380V 50HZ (do as customer's request) |

| Total power | 12KW |

| Overall dimension | 1500×2600×2000mm (L×W×H) |

| Machine weight | 1500Kg |