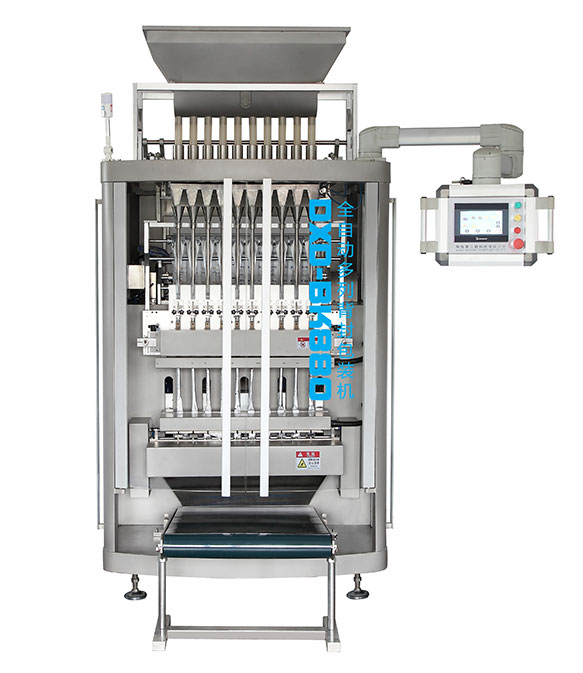

Back Sealing Multi-line Granule Packing Machine can complete everything from longitudinal cutting, back sealing, horizontal sealing, filling... to finished bag output at one time. The equipment adopts modular design, such as film releasing, film drawing and bag making and sealing modules, which can be flexibly configured according to customer's needs to meet different packaging requirements.

The Back Sealing Multi-line Granule Packing Machine adopts advanced technology and equipment, which has high efficiency, stability, durability and safety; The machine has compact equipment structure, simple operation, convenient cleaning, clear and easy-to-understand operation interface, and humanized design to meet the needs of different customers;

Adopt PLC control system and touch screen interface to realize automatic packaging process, stable and reliable double-axis high-precision output and color touch screen.

Packaging scope: suitable for the packaging of granular articles, and the packaging scope can be adjusted according to customer needs;

Packaging materials: a variety of packaging materials, such as paper/plastic aluminum/plastic, can be selected to meet different requirements; It has strong adaptability to packaging materials. The sealing temperature of the machine has automatic control function and high control accuracy (about+1C), and can adapt to various packaging films produced at home and abroad, such as PET/AL/PE, PET/PE, NY/AL/PE and NY/PE.

| Model | DXD-BK800 |

| Lanes number | 6-10 lanes |

| Packing material | Granule |

| Packing speed | 20-60 bags/min/lane |

| Filling capacity | 0.5-50gram/bag |

| Packing film | PET/AL/PE、PET/PE、NY/AL/PE、NY/PE etc. |

| Bag size | L:45-160mm W:24-60 |

| Film width | Max.680mm |

| Sealing type | Back sealing stick type |

| Power supply | 380V 3P 4W50HZ(do as customer's request) |

| Power | 7.8KW |

| Air consumption | 0.8MPA 0.8m³/min |

| Dimension | 1600X1800X2600mm |

| Weight | 2000KG |