The particles are flowed downward by gravity, and installed at a higher position can flow down the river to improve efficiency. In this regard, you must pay attention to the following two points:

1) In order to make the actuator simple and compact, the components of the mechanism should be minimized, and the geometric size and space position should be minimized. The original mover should be as close as possible to the actuator.

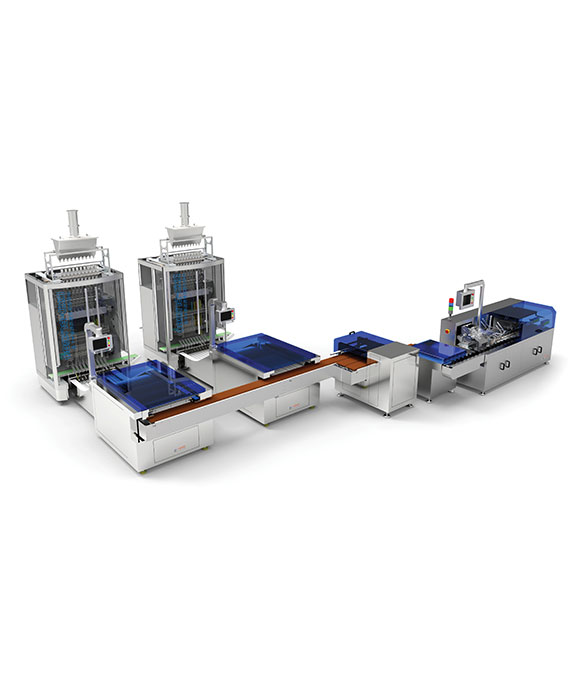

2) In order to simplify the transmission system, facilitate the test and maintenance, and reduce the influence of the transmission damage on the drive tip, the original mover is required to be concentrated as much as possible on one or a few axes. In fact, the execution components are often scattered so that their originals are more difficult to concentrate. At this time, several actuators can be arranged in a centralized manner as one large component. Thus, a packaging machine is equivalent to a number of large components.

Support form selection

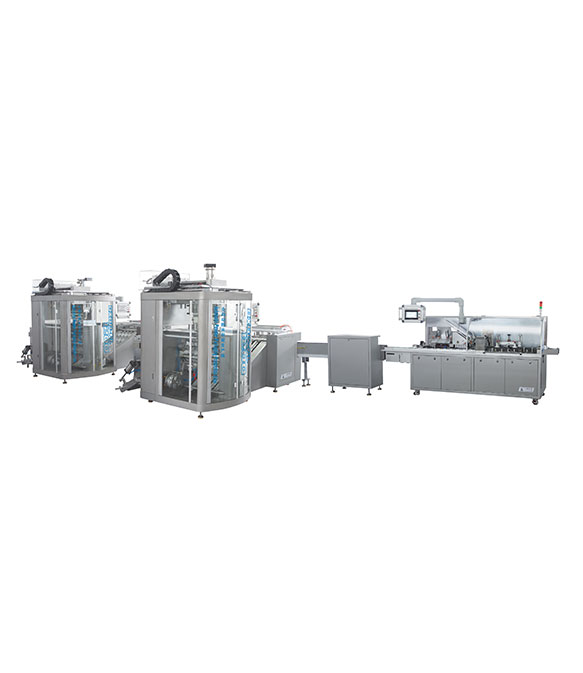

The support of the packaging machine has a base, a box, a column, a beam and the like. The role of the support is to position the components correctly and maintain their relative working position. The requirements for the support are shown:

1) sufficient rigidity, the deformation of the support member when subjected to a large load does not exceed the allowable value;

2) Sufficient vibration resistance is a stable and reliable machine;

3) Moderate quality, strive to save materials, easy to handle;

4) Facilitate the assembly and debugging of parts, operation and maintenance, and the installation and installation of the machine;

5) Beautiful appearance, giving people a sense of harmony, symmetry, stability and safety. Commonly used support forms are "one" type, "1" type, and "mouth" type. Due to the limitation of the working environment and the production is only a small batch batch production, we choose the "1" type, that is, the three-dimensional type. It has a small footprint, flexible operation and compact operation, which is in line with our design requirements.

The circular section has a high torsional stiffness, but the bending strength is poor, so it should be used in a rack that is mainly twisted. The I-shaped section has a high bending strength, but the torsion resistance is low, so it is suitable for a frame that can withstand pure bending. The square section is resistant to bending and the torsion is lower than the I-shaped and circular sections, respectively, and has a certain comprehensive performance. Regardless of the circular, square or rectangular shape, the stiffness of the hollow section is always greater than the stiffness of the solid section, so the support should be made in a hollow form.

In addition, the cross-sectional area is constant, the outline size is increased, the wall thickness is reduced, and even if the material is away from the neutral axis, the bending and torsional rigidity of the cross-section can be improved. From the structural point of view, since the hollow rectangular inner cavity is easy to install other parts, the cross section of many frames often adopts a square or rectangular cross section. Compared with the I-shaped section of the channel section steel, the bending strength is not much different, and the torsional strength is higher than the I-shaped section.

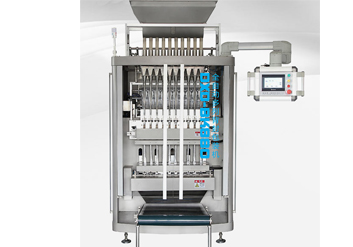

Bag making machine design

The bag forming machine is a key component of the automatic bagging machine. Its function is to transform the flat packaging film material into a cylindrical shape and to produce a sealing edge to facilitate the boring entry of the package. The selection, design and use of the bag forming device directly affects the packaging form of the product, the shape and size of the bag, the quality of the package, and its layout. Therefore, the choice of the former and the design calculation are very important. There are many types of bag-type containers, and this design uses a three-side sealing type. According to the range of applicable package sizes of the bag making machine, the shaper can be divided into two types: the adjustable bag forming device and the special bag forming device. The structural size of the adjustable bag shaper can be adjusted to suit a wide range of product sizes in a range of sizes.