Powder type products are small in size and are prone to powder "backlash" during the packaging process. The "reverse" phenomenon will result in a tight seal of the packaging and will pollute the working environment to a certain extent. Because the vertical packaging equipment is vertically unloaded, the distance between the feeding opening and the bottom of the packaging bag is large, and the bag is made at the same time of packaging. During the blanking process, the material is slipped into the bag with the packaging material as a “slide”. When the powder is lifted, it will contaminate the seal and the seal will not be sealed. As a result, the quality of the product is often affected.

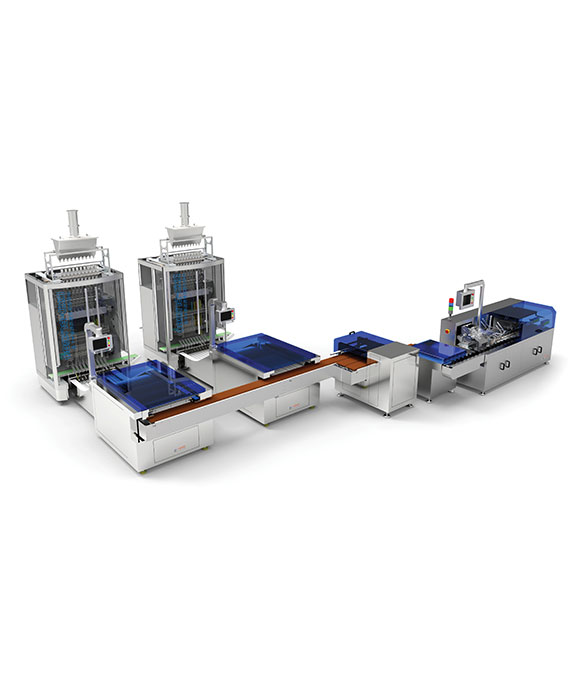

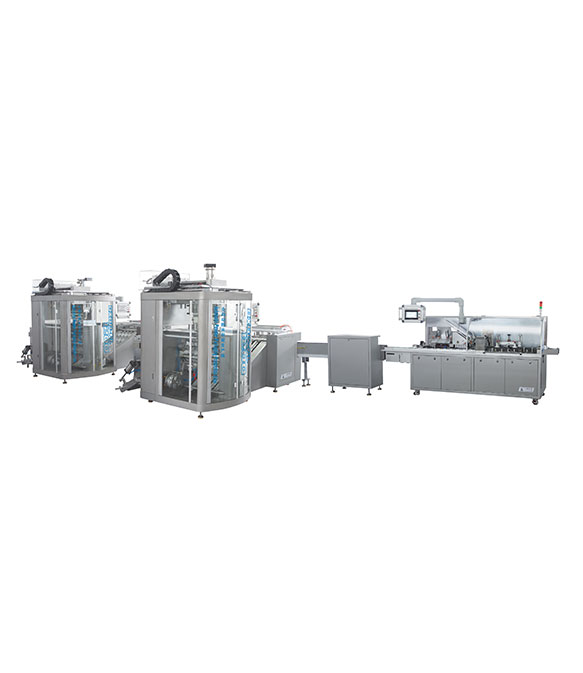

The vertical packaging equipment of Sanyang adopts special feeding system, feeding pipe will be prolonged , and the feeding pipe can directly feed into the bottom of the bag, so as to avoid dust rising. If the powder particles are extremely fine and easily lifted, a dusty suction device can be added to the upper seal to absorb a small amount of powder adsorbed from the bag mouth. This design can completely solve the phenomenon of “reverse”, and guarantee the sealing of the seal to the greatest extent, thus effectively extending the shelf life of the product.