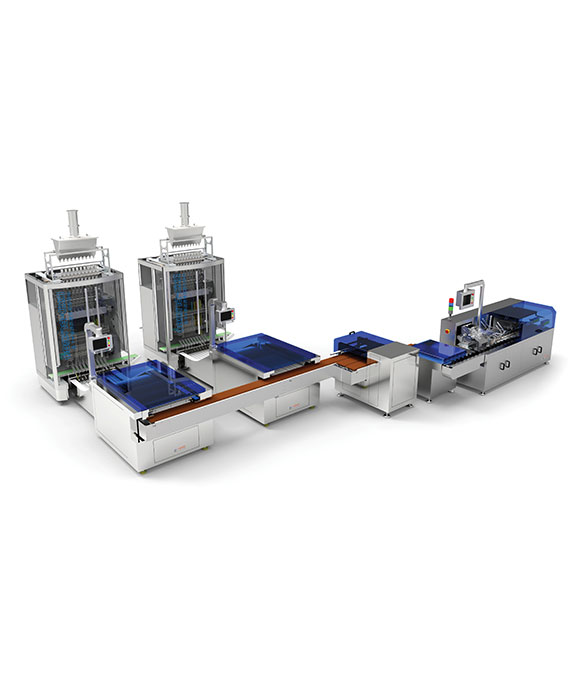

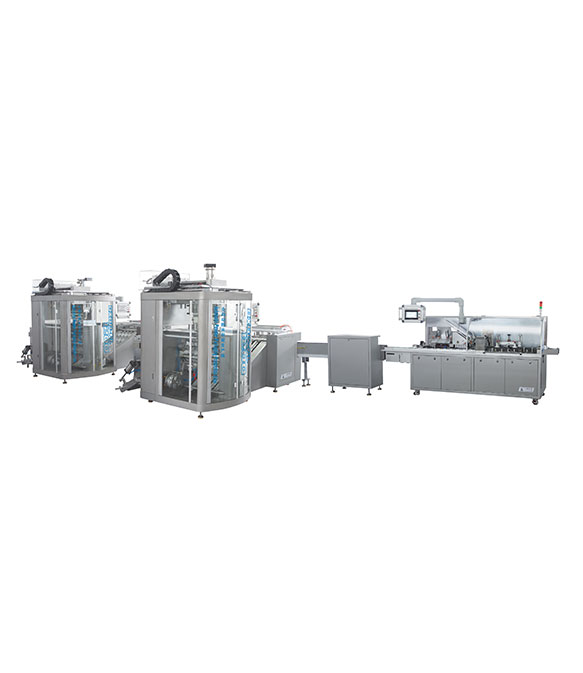

In industrial settings, powder packaging machines are indispensable tools designed to efficiently and accurately package powdered substances into various containers. From pharmaceuticals to food products, these machines play a crucial role in ensuring precise filling, sealing, and labeling of powdered goods, enhancing both productivity and product quality.

1.Features of Powder Packaging Machines

- Versatility: They can handle a wide range of powdered products, including pharmaceuticals, spices, and food items, adapting to different packaging requirements.

- Precision: Equipped with advanced measuring and dispensing systems, these machines ensure exact amounts of powder are filled into each package, minimizing product waste.

- Packaging Options: They offer flexibility in packaging formats, capable of filling and sealing bags, pouches, sachets, bottles, or jars, depending on the specific model and configuration.

- Automation: Many models are fully automated, streamlining the packaging process and reducing labor costs while maintaining consistent packaging quality.

- Hygiene Standards: Designed to meet stringent hygiene standards, these machines help prevent contamination by ensuring a sealed packaging environment.

2.Functions of Powder Packaging Machines

- Filling and Dispensing: They accurately measure and dispense powdered substances into packaging containers, ensuring each package contains the specified amount of product.

- Sealing: Once filled, the machines seal packages securely to maintain product freshness and prevent contamination during storage and transport.

- Labeling: Some advanced models integrate labeling functions to apply product information or branding directly onto packages, enhancing product visibility and compliance.

- Quality Control: Equipped with sensors and monitoring systems, these machines oversee the packaging process to maintain consistent quality and packaging integrity.

3.Conclusion:

powder packaging machines are pivotal in the manufacturing industry for their ability to streamline operations, ensure product quality, and meet hygiene standards. Whether for pharmaceuticals, food products, or industrial applications, these machines offer reliability, precision, and flexibility, supporting efficient production processes and enhancing overall productivity.