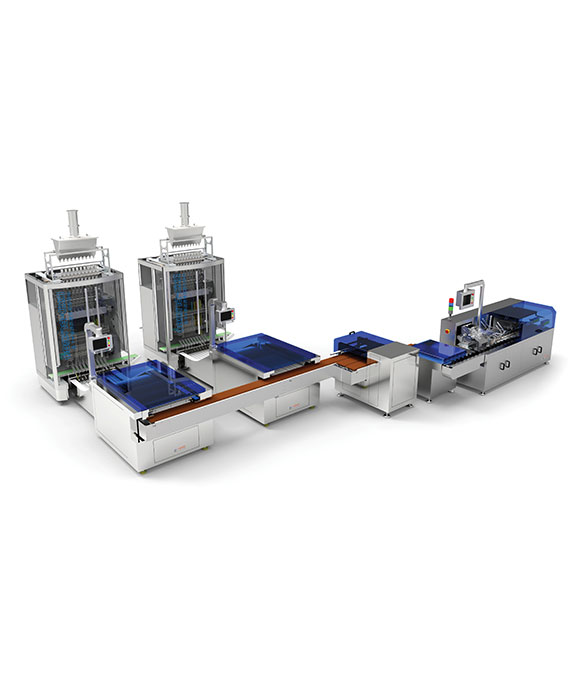

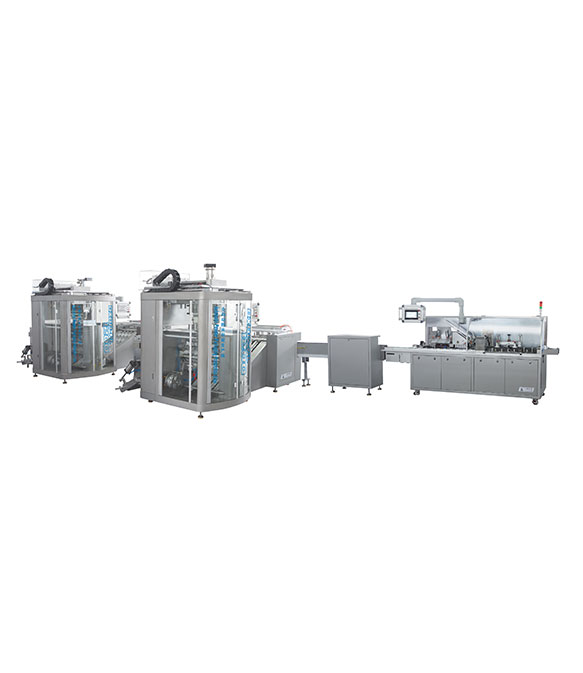

Powder packaging machine is a fully automatic bag packaging equipment designed and manufactured specifically for powder products. This type of machine has accurate and efficient metering functions and can automatically complete the entire process of filling, sealing and cutting.

Main characteristics of powder packaging machine

1. Intelligent automatic packaging technology: powder packaging machinery can fully realize intelligent and accurate measurement of powder, efficient filling, sealing and packaging and other multi-process flows.

2. Accurate measurement system: adopt advanced precision measurement facilities to strictly control the gram weight of powder in each package to ensure the stability of quality and effective control of cost.

3. Flexibly adapt to packaging specifications: according to the actual needs of customers, adjust the packaging specifications and bag types at any time, such as vertical packaging, four-sided sealing packaging, etc., to meet the requirements of various shapes and sizes of packaging bags.

4. Widely applicable to a variety of packaging materials: our machine has strong material adaptability and can easily deal with various packaging materials including composite film, aluminum foil and polyethylene, thus ensuring the sealing performance and fresh-keeping effect of packaging.

5. Easy cleaning and maintenance: the convenience of cleaning and maintenance is fully considered to ensure the sanitary conditions of the production process and the long-term stable operation of the equipment.

How to choose powder packaging machine

When considering choosing a suitable powder packaging machine, the first thing to be clear is the type of powder to be packaged. Different powder types, such as food, chemical, pharmaceutical, etc., have different requirements for packaging machines.

1. Powder type:

Food powder: Food powder usually requires the packaging machine to have high hygiene standards and be made of food-grade materials. In addition, factors such as moisture resistance, oxidation resistance, and pollution resistance need to be considered during the packaging process to ensure the quality and safety of food powder.

Chemical powder: Chemical powder may be corrosive, flammable or have other special properties, so the packaging machine needs to have corresponding protective measures. At the same time, the uniformity and sealing of the powder also need to be considered.

Pharmaceutical powder: Pharmaceutical powder has more stringent requirements for packaging machines, and the purity, sterility and traceability of the powder need to be ensured. The packaging machine usually adopts a fully enclosed design to prevent external contamination and is equipped with a high-efficiency filtration system to ensure air cleanliness.

2. Packaging specifications:

Packaging specifications are another important factor to consider when choosing a powder packaging machine. Determining the weight or volume of each bag of powder, the length and width of the bag making, etc., will help to choose the appropriate packaging machine model and configuration.

3. Daily output:

Choose the appropriate powder packaging machine model and speed according to the daily output requirements of the production line. At the same time, the maintainability and expandability of the packaging machine must also be considered to adapt to possible production changes in the future.

4. Packing form:

Different packaging forms have different requirements for packaging machines. Choose the appropriate packaging form according to actual needs. Back-seal packaging machines are suitable for packaging bags that need to be sealed on the back; three-side seal or four-side seal packaging machines are suitable for packaging bags that need to be sealed on three or four sides.