Granular Packaging Machine: The Packaging Powerhouse of Sanyang Technology

In modern industrial production, the packaging of granular products is of crucial importance, and the granular packaging machine is the core equipment for achieving efficient and precise packaging. Today, let's step into Sanyang Technology and gain an in-depth understanding of the mysteries and outstanding performance of its granular packaging machine.

I. Definition and Basic Principle of the Granular Packaging Machine

-The function of granule packaging machine:

Granule packaging machine is a packaging equipment designed for granular materials, which is indispensable in many industries. Through automated mechanical structure and advanced control system, granular products are packaged according to preset standards.

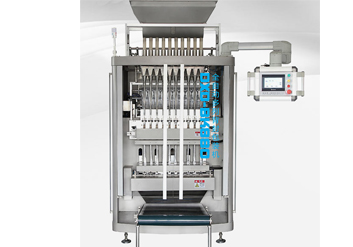

-Innovation of Sanyang Technology Granule Packaging Machine:

High-precision sensors are used to monitor materials in real time, with a metering accuracy of up to ±0.1%, far exceeding industry standards. Advanced mechanical transmission systems enable smooth and efficient material transportation and packaging, reducing jams and errors

II. Features of the Granular Packaging Machine of Sanyang Technology

-Precise Metering

Equipped with a leading metering device, it can handle various materials from powdered sugar to plastic granules, with an accuracy of ±0.1%. For example, in the food industry, the small-bag packaging of chicken essence, coffee powder, etc. is precisely metered, ensuring product quality and brand reputation.

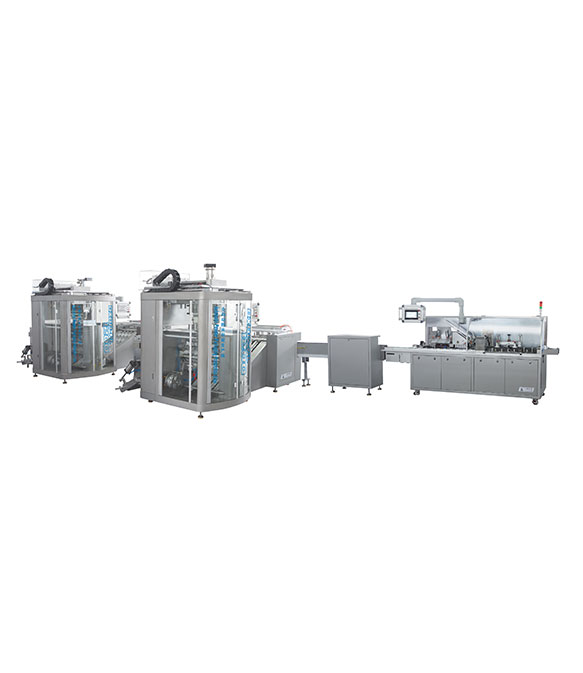

-Diverse Packaging Forms

It can realize common forms such as three-side sealing, four-side sealing, and back sealing, and can also customize special-shaped packaging, compatible with plastic film, paper, composite materials, etc. In the daily chemical industry, the packaging forms of washing powder and laundry detergent granules are rich, meeting different market positioning.

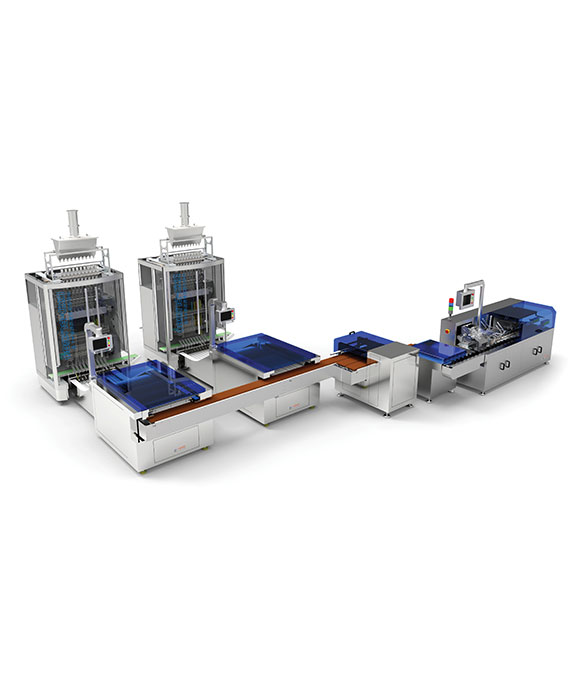

- Highly Efficient Automation

In the chemical industry, in the face of a large number of packaging requirements for fertilizer and pigment granules, it can ensure the rapid operation of the production line, improving efficiency and reducing costs.

- Strong Adaptability

It can excellently handle granular materials with good fluidity or high viscosity and easy caking. In the pharmaceutical industry, various characteristic granular preparations can be accurately packaged, ensuring the stable quality of drugs.

- Intelligent Control and Easy Maintenance

The intelligent control system is easy to operate, with self-diagnosis and early warning of faults, shortening the downtime. The key parts of the equipment are easy to disassemble and install. For example, the cleaning of the metering device and the replacement of wearing parts are convenient, ensuring long-term stable operation.

III. Functions of the Granular Packaging Machine of Sanyang Technology

-Precise Metering and Filling

One of the core functions. Through advanced sensors and algorithms, for example, in the packaging of food seasonings such as pepper powder and cumin powder, the error can be controlled within ±0.5 grams per bag, ensuring consistent usage and enhancing the quality image.

-Sealing and Preservation

Adopting technologies such as heat sealing and ultrasonic sealing, and selecting the appropriate method according to the material and product requirements. Nuts and other products are highly sealed by heat sealing to prevent oil oxidation and moisture absorption and extend the shelf life.

- Identification and Traceability

Some models can add identification such as production date, shelf life, batch number, and QR code. In the pharmaceutical industry, it is convenient for drug traceability management and informationization in logistics and sales, ensuring safety and reliability.

- Quality Inspection and Monitoring

Integrated with multiple inspection functions during packaging. The photoelectric sensor monitors the packaging material, and the weight detection device performs secondary weighing. Products exceeding the error are automatically rejected. It can also be equipped with metal detection to ensure product quality and safety.

IV. Applications of the Granular Packaging Machine of Sanyang Technology in Various Industries

-Wide Application in the Food Industry

Candy production enterprises use it to package various candy granules to attract consumers; the packaging of instant coffee powder, milk tea powder, and other products is precise and moisture-proof and light-proof; the packaging of food additives such as yeast powder and leavening agents is accurate and sealed, meeting the packaging requirements of raw materials.

- Reliable Guarantee in the Pharmaceutical Industry

The production of traditional Chinese medicine granules strictly complies with GMP standards. The precious Chinese herbal medicine granules are precisely metered, and the aseptic sealing prevents deterioration and pollution; the packaging of Western medicine granules is fast and accurate, with clear identification for easy traceability management.

- Efficient Assistance in the Chemical Industry

The packaging of plastic granules can handle products with different particle sizes and densities, with high speed and stability; the fertilizer granules are optimized for packaging according to their characteristics to prevent volatilization and corrosion; the design takes into account safety and environmental protection to ensure the reliability and compliance of the packaging process.

- Innovative Packaging in the Daily Chemical Industry

The packaging forms of washing powder and laundry detergent granules are diverse. The exquisite packaging of bath salts and scrubs enhances the added value. It can also be personalized printed with identification to create a unique brand image.

The granular packaging machine of Sanyang Technology, with its advanced technology, excellent performance, and wide application, has become a leader in the industry. In the future, Sanyang Technology is expected to continue to lead the development of granular packaging machine technology and bring more innovations and breakthroughs to the global packaging industry.