The ketchup sauce pouch filling machine plays a crucial role in the modern food packaging industry, ensuring that ketchup can be packaged into pouches efficiently, accurately, and hygienically. The following is its detailed working principle:

I. Preparation Stage

1.Material Preparation

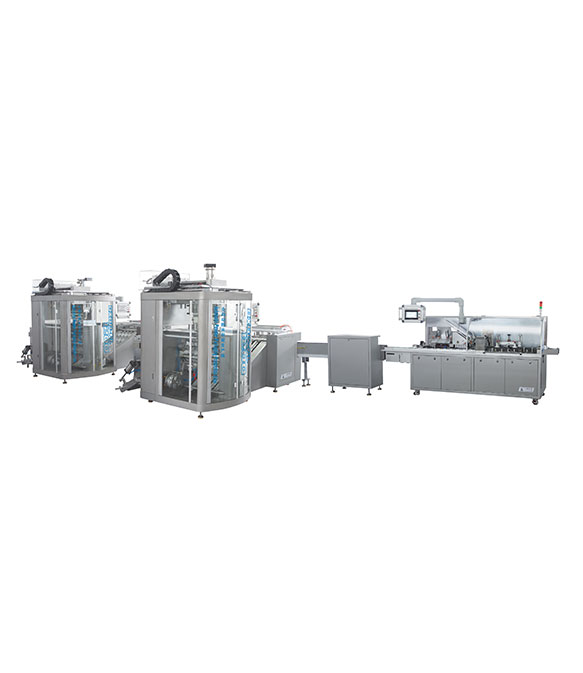

Firstly, the ketchup raw material is stored in a special tank or container. These tanks are usually equipped with a stirring device to prevent the ketchup from settling or layering and to ensure its uniform texture. The stirring device can be a mechanical stirring paddle, which is driven by a motor and rotates at a certain speed to continuously stir the ketchup, making the sauce maintain good fluidity for the subsequent filling operation.

A liquid level monitoring device, such as a liquid level sensor, is also installed on the tank. The liquid level sensor can monitor the liquid level height of the ketchup in real time. When the liquid level is lower than the set minimum value, it will send a signal to remind the operator to replenish the raw material in time to ensure the continuity of the filling process.

2.Packaging Material Preparation

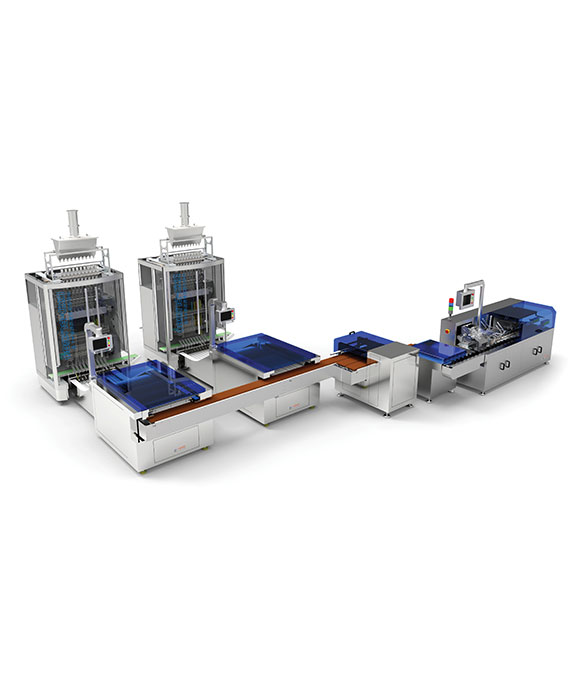

The pouches used for packaging ketchup are usually pre-made composite film pouches with good barrier properties, which can prevent external factors such as oxygen and moisture from affecting the quality of the ketchup. These pouches are placed on the packaging material rack of the filling machine and are transported one by one to the filling position through a specific conveying mechanism.

During the transportation process, the pouches will pass through a series of sorting and positioning devices to ensure that the pouches are in the correct position and posture during filling. For example, there may be guide plates and positioning clips to align the opening of the pouch accurately with the filling nozzle and to make the four sides of the pouch flat for the subsequent sealing operation.

II. Filling Process

a.Measurement and Extraction

When the pouch reaches the filling position, the metering system of the filling machine starts to work. Common metering methods include volumetric metering and gravimetric metering. If it is volumetric metering, there is a precisely designed quantitative chamber inside the filling machine. Through the movement of a piston or valve, a certain volume of ketchup is drawn into the chamber. This volume is determined according to the preset filling amount, such as common packaging specifications of 100 grams, 200 grams, etc.

If it is gravimetric metering, a high-precision weighing sensor is used. The sensor first weighs the empty pouch and then monitors the total weight of the pouch and ketchup in real time during the filling process. When the preset weight is reached, the filling system will stop filling immediately to ensure the accurate weight of each pouch of ketchup.

b.Filling Action

The measured ketchup is injected into the pouch through the filling pipeline and filling nozzle. The design of the filling nozzle is very important. It usually adopts a special structure, such as a nozzle with an anti-drip device. When the filling is completed, the anti-drip device can quickly close the nozzle to prevent the ketchup from remaining at the filling head and dripping onto the packaging machine, which not only ensures the hygiene of the packaging but also avoids the waste of raw materials.

During the filling process, in order to ensure that the ketchup can flow smoothly into the pouch without generating bubbles or splashing, the filling speed and pressure need to be precisely controlled. The filling machine is equipped with a flow regulating device and a pressure control system. According to factors such as the viscosity of the ketchup and the size of the pouch, the appropriate filling speed and pressure are adjusted. For example, for thicker ketchup, a lower filling speed and higher pressure may be required to ensure that the sauce can fill the pouch evenly; while for thinner ketchup, the filling speed can be appropriately increased, but it is also necessary to prevent the sauce from overflowing due to excessive speed.

III. Sealing Operation

1).Sealing Method Selection

The ketchup sauce pouch filling machine usually adopts heat sealing for sealing. Heat sealing uses a heating element to heat the opening part of the pouch, melting and fusing the plastic film of the pouch together to form a seal. Common heat sealing methods include impulse heat sealing and continuous heat sealing. Impulse heat sealing heats the sealing part intermittently by applying a high-voltage pulse, which is suitable for pouches of different thicknesses and materials and can accurately control the sealing temperature and time. Continuous heat sealing uses a continuous heating element to seal the pouch, with a faster sealing speed and is suitable for large-scale production.

2).Sealing Process

To ensure the sealing quality, the sealing device is also equipped with a temperature monitoring and pressure adjustment system. The temperature monitoring system monitors the temperature of the sealing part in real time. When the temperature deviates from the set range, it will automatically adjust the heating power to keep the temperature stable. The pressure adjustment system can adjust the sealing pressure according to factors such as the material and thickness of the pouch to ensure that the seal is flat, tight, and leak-free.

IV. Finished Product Output and Quality Inspection

3).Finished Product Output

The sealed finished ketchup sauce pouches will be transported to the finished product collection area of the packaging machine through a conveyor belt or other conveying devices. During this process, some sorting and arranging devices may be passed through to make the finished pouches neatly stacked or arranged, facilitating the subsequent boxing or packaging operations.

Operators can conduct a preliminary visual inspection of the packaged ketchup in the finished product collection area, such as checking whether the pouch is damaged, whether the seal is good, and whether the label is pasted correctly. If any defective products are found, they can be removed in time to prevent defective products from entering the market.

4).Quality Inspection

To ensure product quality, some online quality inspection equipment can also be equipped during the production process. For example, a metal detection device can detect whether there are metal foreign objects mixed in the ketchup to ensure food safety. A weight detection device can conduct a secondary weighing of the finished products to further check whether the weight of each pouch of ketchup meets the standard. If any products with excessive weight deviation are found, they will be automatically removed. In addition, a visual inspection system can also be used to comprehensively inspect the appearance, printing quality, and sealing quality of the pouches to improve the overall quality level of the products.

The ketchup sauce pouch filling machine realizes the efficient and high-quality packaging of ketchup through the above series of rigorous and precise working steps, meeting the packaging needs of the ketchup product market and also ensuring the quality and hygienic safety of the products. With the continuous development of the food packaging industry today, the technology of the filling machine is also constantly innovating and improving to adapt to more diverse products and higher production requirements.