In the field of liquid packaging, the price and cost-effectiveness of liquid packaging machines have attracted much attention. Understanding the factors affecting price fluctuations and deeply analyzing cost-effectiveness can help enterprises make rational decisions and achieve efficient production and optimal resource allocation.

I. Factors Affecting the Price Fluctuations of Liquid Packaging Machines

(I) Brand Influence

Well-known brands usually have greater pricing power in the liquid packaging machine market. These brands have accumulated rich experience in technological research and development, mature production processes and a broad customer base through long-term market cultivation. For example, international big brands like Tetra Pak have won a high reputation worldwide for their liquid packaging machine products with excellent quality, advanced technology and reliable after-sales service. Consumers have a higher level of trust in such brands and are willing to pay higher prices for their products. In contrast, some emerging or niche brands usually attract customers with relatively lower prices in order to gain a foothold in the market, but they are relatively weaker in terms of brand awareness and reputation, and their product prices are also somewhat limited.

(II) Technological Innovation and Functional Features

Degree of Automation: Liquid packaging machines with a high degree of automation can significantly improve production efficiency, reduce human intervention and lower labor costs. For example, packaging machines equipped with integrated functions such as automatic feeding, filling, sealing and labeling are more expensive than those with single functions that require more manual operations. The application of advanced automation control systems, such as programmable logic controllers (PLC), enables precise control of the production process, which also increases the cost of the equipment.

Filling Accuracy: For liquid packaging machines, filling accuracy is of vital importance. High-precision filling equipment can ensure that the liquid volume in each packaging container has a minimal error. This is especially crucial in industries with strict dosage requirements, such as the pharmaceutical and food additive industries. Packaging machines using high-precision flow sensors, metering pumps and advanced filling algorithms will see their prices rise due to the technical complexity.

Packaging Speed: Liquid packaging machines with a high packaging speed can handle more products per unit time and meet the needs of large-scale production. High-speed packaging machines are usually equipped with high-performance motors, transmission systems and optimized mechanical structures to ensure fast and stable operation. However, these high-performance components and designs will greatly increase the manufacturing cost of the equipment, thus leading to a price increase.

(III) Equipment Specifications and Production Capacity

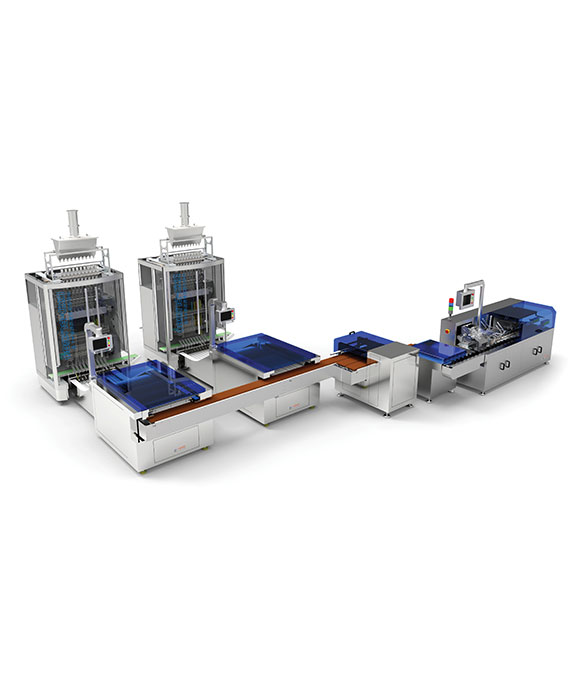

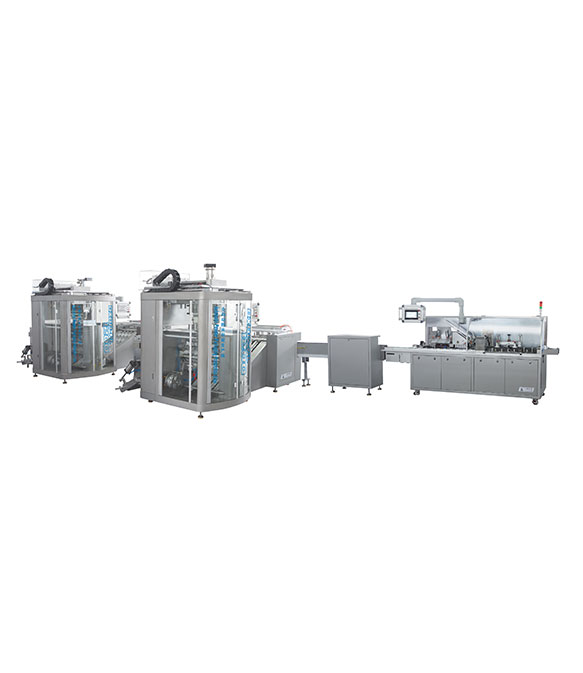

The size and production capacity of liquid packaging machines are directly related to their prices. Large packaging machines with high production capacity, such as high-speed and large-capacity packaging machines used in beverage production lines, have a more solid body structure, require more powerful power systems, more filling heads and more complex control systems. These factors make the manufacturing cost of large equipment much higher than that of small packaging machines with lower production capacity. For example, a large production line packaging machine that can package thousands or even tens of thousands of bottles of liquid products per hour may cost several million yuan, while a small desktop packaging machine that can only package a few hundred bottles per hour may only cost tens of thousands of yuan.

(IV) Cost of Raw Materials

The manufacture of liquid packaging machines relies on various raw materials, such as stainless steel, electronic components, motors, conveyor belts, etc. Fluctuations in the prices of raw materials will have a direct impact on the prices of the equipment. When the price of stainless steel rises, the costs of the packaging machine body, filling parts and other components made mainly of stainless steel will increase, thus driving up the price of the whole machine. Similarly, changes in the prices of electronic components, especially those of key components such as high-precision sensors and controllers, will also have a significant impact on the final price of liquid packaging machines.

(V) Market Supply and Demand Relationship

The market supply and demand situation is an important macro factor affecting the prices of liquid packaging machines. During periods when market demand is strong and supply is relatively insufficient, such as in the rapid development stage of emerging industries, the demand for liquid packaging machines increases sharply, while the production capacity of manufacturing enterprises cannot keep up in time. At this time, the prices of the equipment will rise. On the contrary, when the market is highly competitive and supply exceeds demand, in order to compete for limited customer resources, liquid packaging machine manufacturing enterprises will reduce prices to improve the competitiveness of their products, resulting in a price decline. For example, in some traditional industries, as the market saturation increases, the prices of liquid packaging machines often face greater downward pressure.

(VI) Customization Requirements

Some enterprises need to customize liquid packaging machines due to the particularity of their products, such as special packaging shapes, sizes, requirements for packaging materials or unique filling processes. Customized production means that manufacturing enterprises need to invest more resources in research and development and design, develop personalized molds, write programs and conduct equipment debugging. Moreover, the production batches of customized equipment are usually small, and the costs cannot be shared through large-scale production like standardized products. Therefore, the prices of customized liquid packaging machines are generally much higher than those of ordinary standard models.

II. Cost-Effectiveness Analysis of Liquid Packaging Machines

(I) Small Enterprises and Start-ups

Meeting Basic Functions: For small enterprises and start-ups, capital is relatively limited and the production scale is small. Their main demand for liquid packaging machines is to meet basic packaging functions. Some relatively affordable small semi-automatic liquid packaging machines or basic fully automatic liquid packaging machines are good choices. Although these devices may not be as advanced as high-end equipment in terms of the degree of automation and packaging speed, they can complete basic operations such as liquid filling and sealing. And their prices are usually between tens of thousands of yuan and hundreds of thousands of yuan, offering relatively high cost-effectiveness.

Flexibility and Expandability: Small enterprises may often adjust their product types and production processes in the early stage of development. Therefore, it is more appropriate to choose liquid packaging machines with a certain degree of flexibility and expandability. For example, some equipment can easily replace filling heads or adjust packaging specifications, which can adapt to the future development and changes of enterprises to some extent and avoid the cost increase caused by the need to frequently replace equipment due to overly fixed equipment.

(II) Medium-sized Enterprises

Balance between Performance and Price: Medium-sized enterprises usually have a certain market share and stable production requirements, and they have relatively high requirements for the performance of liquid packaging machines. At this stage, choosing medium-to-high-end liquid packaging machines can achieve a good balance between performance and price. The prices of such equipment are generally around several hundred thousand yuan. They have a relatively high degree of automation, good filling accuracy and fast packaging speed, which can effectively improve production efficiency, reduce labor costs and enhance the quality of products, thereby strengthening the competitiveness of enterprises in the market.

When choosing liquid packaging machines, medium-sized enterprises should pay attention to brand selection. Well-known brands not only offer better product quality but also have more complete after-sales services. Timely equipment maintenance, technical support and regular maintenance can reduce equipment downtime and ensure the continuity of enterprise production. In the long run, this is also an important manifestation of cost-effectiveness.

(III) Large Enterprises

Efficient Large-scale Production: Large enterprises have a huge production scale and extremely high requirements for the production capacity, stability and reliability of liquid packaging machines. Although high-end large liquid packaging machines are expensive, often costing millions or even tens of millions of yuan, they can achieve efficient and stable large-scale production. For example, some advanced high-speed liquid packaging production lines can package tens of thousands or even hundreds of thousands of bottles of liquid products per hour, which can significantly reduce the packaging cost per unit product and improve the overall production efficiency of enterprises.

Technological Leadership and Long-term Investment: Large enterprises usually attach more importance to the technological leadership of liquid packaging machines in order to maintain their competitive advantage in the industry. Investing in purchasing packaging machines with the latest technologies, such as intelligent control systems and energy-saving and environmental protection technologies, although the initial investment is huge, from the perspective of long-term development and strategic investment, these technologies can bring higher production efficiency, better product quality and more environmentally friendly production methods to enterprises, and have high cost-effectiveness and long-term investment value.