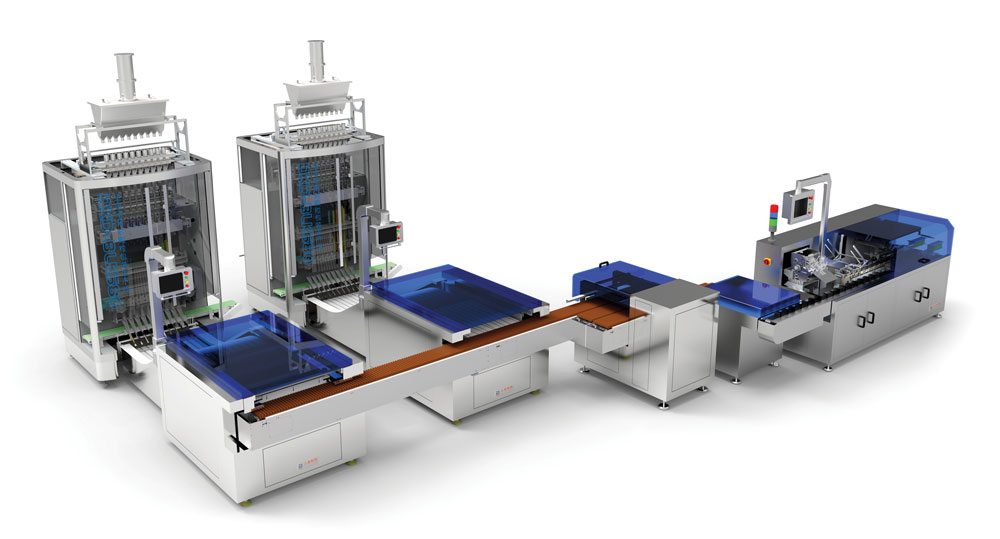

The Paste Back Sealing Carton Packing Production Line is suitable for the pharmaceutical, food, daily chemical and other industries, and is specially used for the packaging of viscous liquids and thick paste materials. It can automatically put peanut oil, salad oil, ketchup, cough syrup, shampoo, cream oil, vaseline and other materials into small bags according to the measurement requirements, and then put the small bags into small boxes.

Advanced control system: PLC control is adopted, servo tracking synchronous linkage, easy operation, reliable performance, and high degree of automation.

Fully automatic operation: from longitudinal cutting, back sealing, transverse sealing, filling, coding, easy tearing, transverse cutting to finished bag output, it is completed in one go.

Efficient packaging: using a combined sealing knife mold, back sealing and upper and lower transverse sealing alternately multiple rows of one-time sealing, ensuring tight sealing, fast speed, flat and beautiful bag shape, and improving packaging efficiency.

Convenient adjustment: no need to change the mold, the bag length, longitudinal sealing, transverse sealing, filling and transverse cutting operations can be adjusted steplessly through the human-machine interface.

Accurate measurement: a special plunger reciprocating sauce pump is set to ensure accurate measurement and convenient adjustment of the sauce in each row of bags.

Precise control: The bag forming process is controlled by PLC to ensure accurate positioning and automatic synchronization of each actuator.

Photoelectric tracking system: Automatically mark the bag, with automatic counting function, and more intelligent operation.

Strong adaptability: Applicable to a variety of packaging films produced at home and abroad, with high automatic control accuracy of sealing temperature.

Additional functions: Optional bag cutting functions such as flat knife, dotted line knife, sawtooth, rounded corners, as well as typing and coding equipment such as ink wheel and laser printer can meet different alarm needs.

|

Model |

DXD-BJ800 |

|

Lanes number |

5-10lanes |

|

Packing material |

Paste |

|

Packing speed |

20-40bags/min/lane |

|

Filling capacity |

1-50gram/bag |

|

Packing film |

PET/AL/PE、PET/PE、NY/AL/PE、NY/PE etc. |

|

Bag size |

L:45-160mm W:24-60 |

|

Film width |

Max.800mm |

|

Sealing type |

Back sealing/ stick type |

|

Power supply |

380V 3P 4W50HZ(do as customer's request) |

|

Power |

10-20KW |

|

Air consumption |

0.8MPA 0.8m³/min |

|

Dimension |

1900X1600X3200mm |

|

Weight |

3000KG |

|

Model |

SYZ-120 |

||

|

Encasing speed |

30-100 Cartons/min |

||

|

Sachet quantity |

1-12 bags, Base on sachet or pouch size |

||

|

Carton |

Quality requirement |

250-350g/m², Base on carton size |

|

|

Dimension range(LxWXH) |

(70-180)mm×(35-85)mm×14-50)mm |

||

|

Leaflet |

Quality requirement |

60-70g/m² |

|

|

Unfolded leaflet specification |

(80-250)mm×(90-170)mm |

||

|

Fold range |

【1-4】 Fold |

||

|

Compressed air |

Working pressure |

≥0.6Mpa |

|

|

Air consumption |

260-300L/min |

||

|

Power supply |

220V 50Hz |

||

|

Motor power |

2.2kw |

||

|

Machine dimension (L×W×H) |

4200mm×1050mm×1600mm |

||

|

Machine weight |

1600kg |

||