Automatic Granule Packaging Production Line is suitable for the packaging of loose, non-sticky granular materials in the pharmaceutical, food, daily chemical and other industries. The materials are automatically packed into small bags according to the metering requirements, such as Chinese medicine granules, coffee, etc.; crystalline materials such as monosodium glutamate, sugar, salt, etc.; low heat materials such as Chinese patent medicine, medicine, etc.

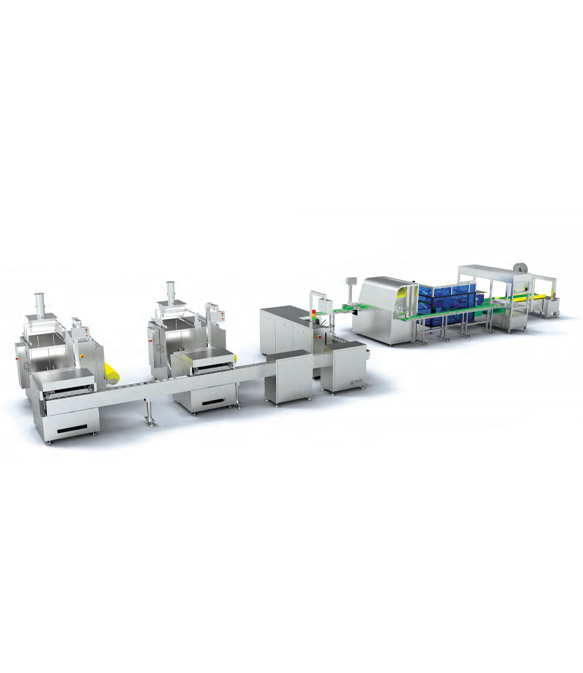

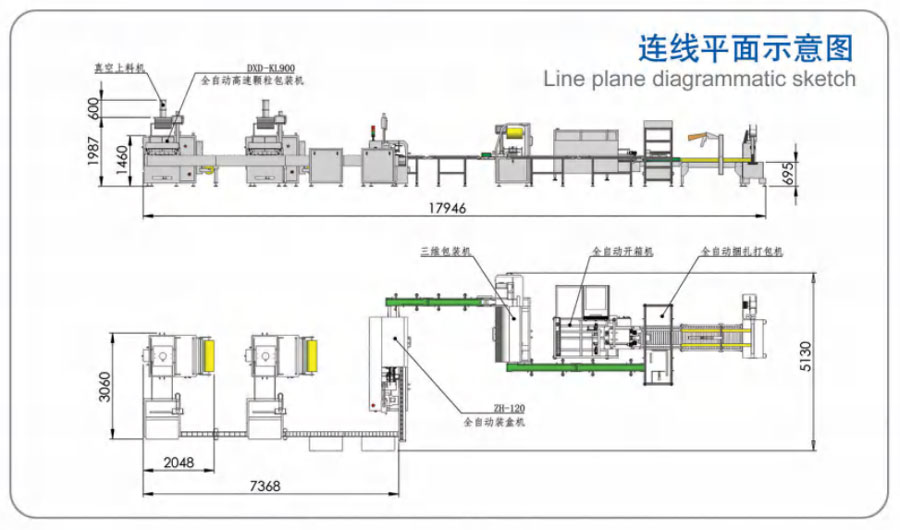

This Automatic Granule Packaging Production Line mainly consists of two DXDO-K900F fully automatic granule packaging machines: small bag sorting and conveying, online weighing, detection and rejection, counting and stacking bag conveying, cartoning machine, three-dimensional packaging machine, boxing and strapping, etc.

The main feature of this packaging production line is that a three-dimensional packaging machine and a boxing and strapping machine are added behind the original boxing machine production line, making the production line more complete. The single-box three-dimensional boxing, box body strapping and other processes can be completed online continuously and fully automatically, and the main components are controlled by servo motors.

The equipment can also perform online dynamic weight detection and automatic waste rejection, and can complete automatic feeding, bag making, filling, longitudinal sealing, transverse sealing, batch number printing, tearing, flat cutting, bag retrieval, sorting and conveying, online weighing, bag leakage, automatic counting of finished bags, stacking, manual folding, carton forming, finished product bagging and boxing, batch number printing, waste rejection, three-dimensional carton packaging, product counting, finished product packaging and bundling output and other processes. It is an ideal fully automatic online production equipment (four-side sealed packaging bags for granular materials).

DXDO-K900F

| Pouch length range | 50-150mm |

| Pouch width range | 40-105mm |

| Packing speed | 40-60 times/min |

| Filling capacity | 0.5-50ml |

| Max film width | 900mm |

| Working pressure | 0.7Mpa |

| Air consumption | 0.8m3/Min |

SYZ-120

| Running speed | 10-100 boxes/min | |

| Carton | Quality requirement | 250-300g/m² |

| Dimension range | (70-180)×(30-85)×(14-50)mm | |

| Leaflet | Quality requirement | 60-70g/m² |

| Size of unfolded leaflet | (80-250)×(90-170)mm | |

Three Dimensional Packing

| Packing speed | <300small boxes (20-30)middle box/min |

| Package Size | (300-60)×(240-40)×(125-15)mm |

| Film width | Options according to package size |

| Sealing temperature | 100-140℃ |

Corton Packing

| production capacity | 1-6 carton/min |

| Carton size | (200-580)×(120-400)×(110-400)mm |

| Packaged products size | Max: 500×350×350mm |

| Packing number | 30-90 carton |