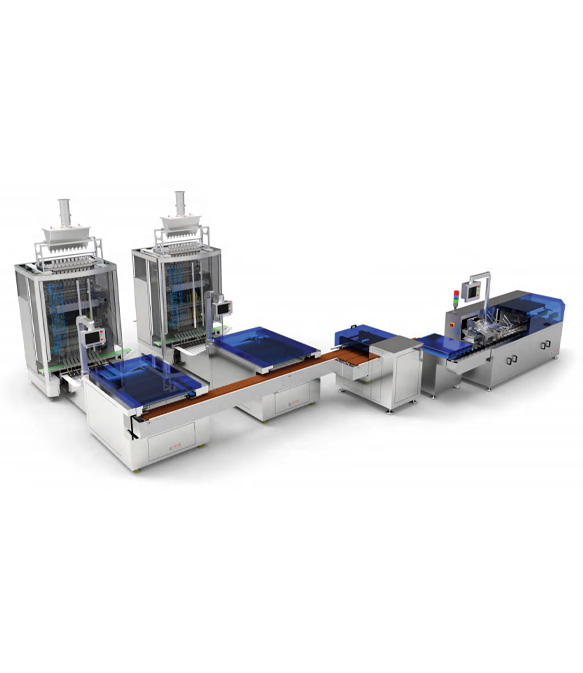

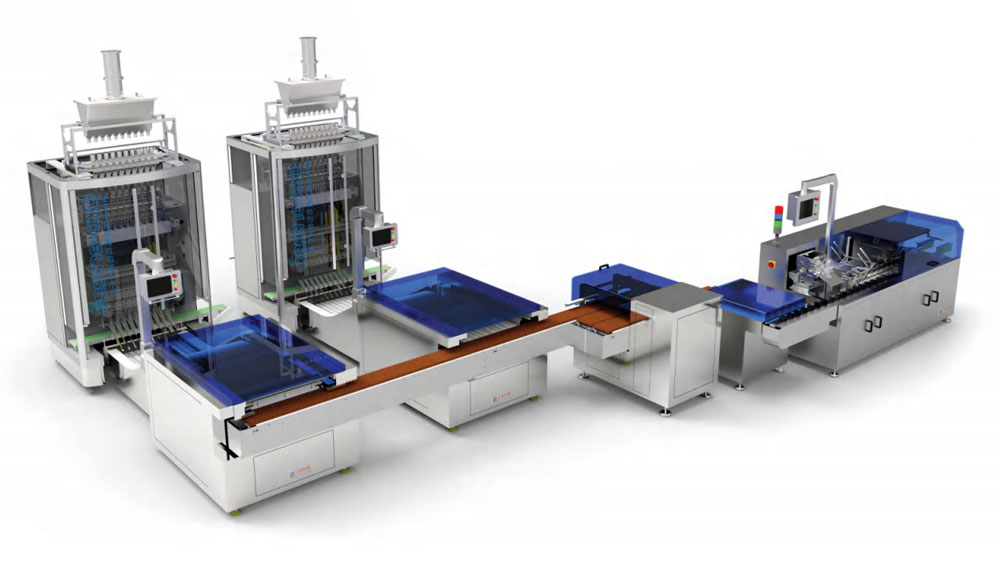

The Fully Automatic Granule Back Sealing Sachet Packing Carton Production Line is designed for the pharmaceutical, food, daily chemical and other industries, and is particularly suitable for automatic packaging of granular materials and small and medium-sized bags with metering requirements. Whether it is pills, granules, coffee, sugar, monosodium glutamate or small granule pharmaceutical preparations, this production line can achieve efficient and accurate packaging.

1. Highly automated: It integrates automatic feeding, box opening, box entry, batch numbering, box sealing, waste rejection and other functions to achieve unmanned operation throughout the process, reduce labor costs and improve production efficiency.

2. Compact and reasonable structure: The production line has a compact layout and a small footprint, which is convenient for deployment in various production environments. At the same time, the reasonable structural design ensures the stability and durability of the equipment.

3. Easy to operate: It adopts servo/stepper motors, touch screens, and PC programmable control systems. The human-machine interface is clear and easy to understand, and the operation is simple. Users can easily complete the setting and adjustment of various parameters of the equipment.

4. Highly user-friendly design: During operation, the equipment can automatically detect and handle abnormal situations, such as empty bags not being unpacked, etc., effectively avoiding material waste and improving production efficiency.

1. advanced performance, high strength, low noise, compact structure, stable operation, easy maintenance, long service life.

2 the whole machine adopts PLC control, servo tracking synchronous linkage, reliable performance, convenient operation, high degree of automatic control.

3 high degree of automation. This machine from the longitudinal cutting, longitudinal sealing, transverse sealing, filling, printing, notch cutting, cross cutting, until the finished bag output can be completed at one time.

4 adopt the combination sealing knife as sealing mould. Back sealing, upper and lower transverse sealing alternating multiple times once sealing. Sealing tightly. And with high packing speed, pouch shape smoothly, delicate appearance, high packing efficiency.

5 quick and convenient adjustment. The bag length can be adjusted without changing the mould. And the vertical seal, transverse sealing, filling, cutting and other implementing agencies can be adjusted through the man-machine interface.

6 filling measurement accuracy. In the case of granular materials, it is specially designed to push and pull the whole metering plate or triangle measuring cup method, and each bag can be adjusted conveniently and accurately.

7 in the forming process of the packaging bag through the PLC control, so that each actuator can be accurately automatic positioning.

8 photoelectric tracking system is adopted to ensure the automatic calibration of the packaging bag, and has the function of automatic counting.

9 strong adaptability to the package material, the sealing temperature of the machine has the function of automatic control, and the control precision is high (about 1C degrees). Can adapt to domestic and foreign production of a variety of packaging films, such as PET/AL/PE, PET/PE, NY/AL/PE, NY/PE, etc..

10 additional features can be added, such as the right to cut off the choice of cutting machine, dashed knife, serrated knife, etc.. Typing code can be selected ink wheel printer, etc., and the selection of various alarm requirements.

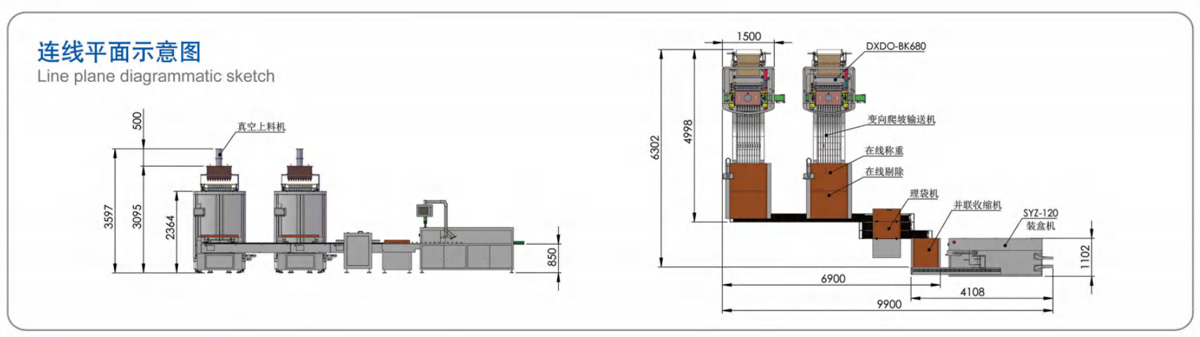

DXD-BK800

| Pouch length range | 50-160mm (adjustable) | |

| Pouch width range | 20-60mm | |

| Packing speed | 30-50 times/min | |

| Filling capacity | 1-50ml | |

| Max film width | 680mm | |

SYZ-120

| Running speed | 10-100 boxes/min | |

| Carton | Quality requirement | 250-300g/m² Based on box size |

| Dimension range | (70-180)×(35-85)×(14-50)mm (LxWxH) | |

| Leaflet | Quality requirement | 60-70g/m² |

| Size of unfolded leaflet | (80-250)x(90-170)mm | |

DXD-BK800 Production Line

| Total capacity | 30-90 boxes/min | |

| Power supply | 380V 50Hz | |

| Total power | 35KW | |

| Compressed air | Working pressure | 0.7Mpa |

| Air consumption | 0.8m³/Min | |