The application of cartoning machines in the packaging industry has many advantages, which not only improve production efficiency and product quality, but also reduce the production costs of enterprises and enhance the market competitiveness of enterprises. The following are the specific application advantages of cartoning machines in the packaging industry:

1. Improve production efficiency

Automated operation: The cartoning machine adopts an advanced automated control system, which can quickly and accurately complete a series of processes such as product packing, sealing, and packaging. Compared with the traditional manual packaging method, the cartoning machine can greatly improve production efficiency and reduce the time and error of manual operation.

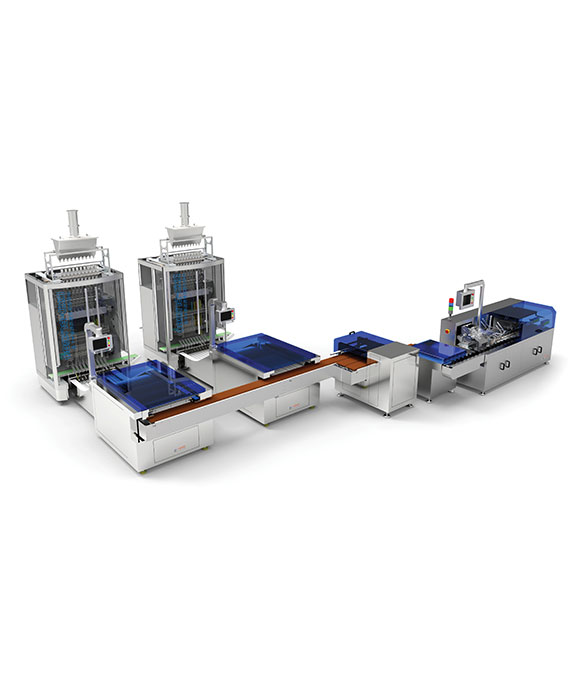

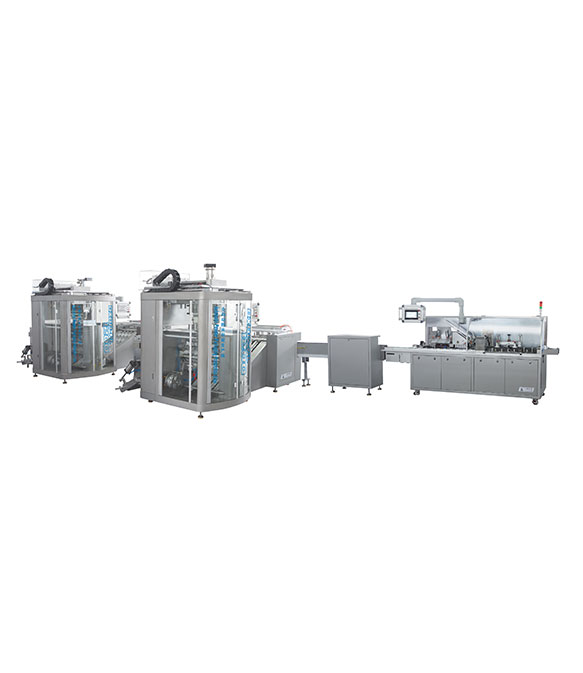

Continuous working ability: Both horizontal cartoning machines and upright cartoning machines have the ability to work continuously, and can be flexibly adjusted according to production needs to ensure the continuity and efficiency of the production line.

2. Reduce production costs

Reduce labor costs: Cartoning machines can greatly reduce the labor required for manual packaging, thereby reducing labor costs. Especially in large-scale production, this advantage is more obvious.

Reduce energy consumption: The cartoning machine adopts advanced control systems and mechanical structures, which can achieve efficient and low-consumption operation, reduce energy consumption and maintenance costs.

Reduce scrap rate: The cartoning machine can better control the details of the product packing quantity, arrangement and other details during the packaging process, reduce packaging problems caused by human factors, thereby reducing scrap rate and improving production efficiency.

3. Ensure product quality

Precise control: The cartoning machine can ensure the accuracy and consistency of the product during the packaging process, and reduce packaging problems caused by human factors. For example, through photoelectric monitoring and PLC control programs, the position and quantity of each product can be accurately controlled.

Automatic detection and screening: Some high-end cartoning machines also have automated detection and screening functions, which can ensure that only products that meet quality requirements can enter the packaging link, further improving product quality.

4. Strong adaptability

Adapt to a variety of products: The cartoning machine has strong adaptability and can handle products of various shapes, specifications and sizes. Through simple adjustments and configurations, the cartoning machine can adapt to new product lines and production needs.

Quickly change specifications: For example, the horizontal cartoning machine, the box body of its product specifications can be quickly changed, and the speed is one or two times faster than the vertical cartoning, which is particularly suitable for scenes with high production speed requirements.

5. Enhance corporate image and brand value

Modernized image: The automated packaging process can show the modern, professional and efficient image of the enterprise, and enhance consumers' trust and goodwill in the enterprise.

Exquisite packaging: The cartoning machine can also achieve exquisite packaging effects, improve the appearance quality and attractiveness of the product, and further enhance the brand value.

6. Easy to manage and monitor

Real-time monitoring: The cartoning machine is equipped with advanced control systems and monitoring equipment, which can realize real-time monitoring and data recording of the production process. This enables enterprises to manage and optimize the production process more conveniently.

Data analysis: Through data analysis and mining, enterprises can also understand the bottlenecks and problems in the production process, providing strong support for improving production processes and improving production efficiency.

In summary, the application of cartoning machines in the packaging industry has many advantages, which not only improve production efficiency and product quality, but also reduce the production costs of enterprises and enhance the market competitiveness of enterprises. With the continuous advancement of science and technology and the continuous increase in market demand, the application prospects of cartoning machines in the packaging industry will be broader.