In the world of packaging, sachets are a popular choice for a wide variety of products. Two common types of sachets are the 4-Side-Seal-Sachet and the 3-Side Seal Sachet, each with its own unique characteristics and applications.

I. Structural Differences

1. Sealing Sides

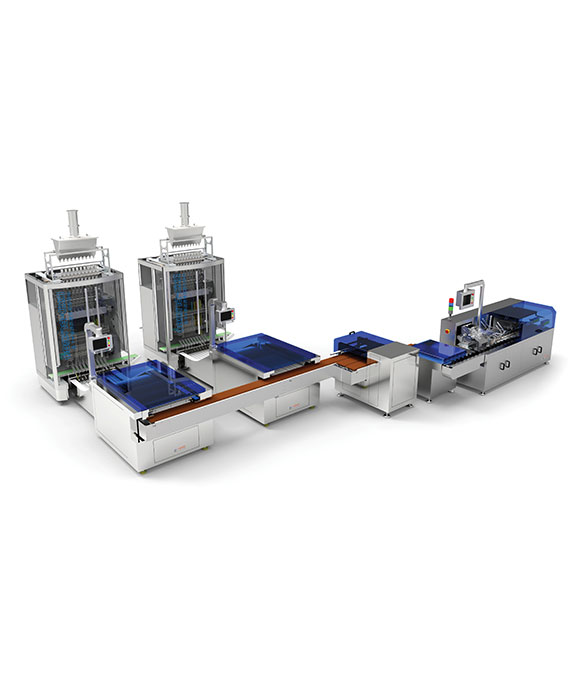

The most obvious difference lies in the number of sealed sides. As the name suggests, a 4-Side-Seal-Sachet has all four sides sealed. This creates a more enclosed and secure package. The top and bottom, as well as the two side edges, are carefully sealed, providing a complete enclosure for the contents.

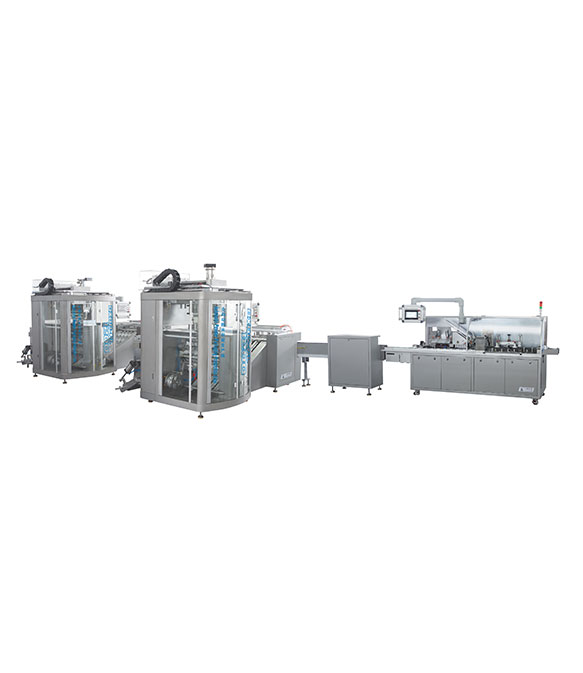

In contrast, a 3-Side Seal Sachet has only three sides sealed. Typically, the two side edges and one of the horizontal edges (either the top or the bottom) are sealed. This leaves one side open for filling the product and is then sealed after the filling process is complete.

II. Functional Differences

1. Product Protection

4-Side-Seal-Sachets offer enhanced protection due to their complete enclosure. They are better at preventing moisture, air, and other contaminants from entering the package. This makes them ideal for products that are sensitive to environmental factors, such as certain pharmaceuticals, food items with a long shelf life, or electronic components that need to be protected from moisture and static electricity.

3-Side Seal Sachets provide a reasonable level of protection, especially for products that are not highly sensitive. However, the unsealed side may be a potential entry point for small amounts of air or moisture over time. For example, they are commonly used for single-use items like tea bags, coffee sachets, or small samples of cosmetics where the exposure to the environment during a short period of use is not a major concern.

2. Filling and Packaging Efficiency

4-Side-Seal-Sachets are often more suitable for automated filling processes. The four sealed sides provide a more stable structure during the filling operation, allowing for higher precision and speed. They can also be designed with features like tear notches or zip-lock closures for easy access and resealing, which is beneficial for products that may be used in multiple doses or need to be stored after opening.

3-Side Seal Sachets are relatively easier and more cost-effective to produce in small quantities or for manual filling operations. The open side allows for simple and quick filling, especially for loose or granular products. However, they may not be as efficient in high-speed automated packaging lines as 4-Side-Seal-Sachets due to the need to carefully control the sealing of the open side.

III. Cost and Material Usage Differences

1. Material Consumption

4-Side-Seal-Sachets generally require more packaging material compared to 3-Side Seal Sachets. The additional sealing on the fourth side means more material is used in the manufacturing process. This can have an impact on the overall cost of the packaging, especially for large-scale production where material costs can be a significant factor.

3-Side Seal Sachets use less material, which can make them a more economical choice for products where cost is a major consideration and the additional protection of a 4-Side-Seal-Sache{ts is not essential. For example, for promotional samples or inexpensive consumer goods, the savings in material cost can be significant.

2. Production Cost

The production cost of 4-Side-Seal-Sachets is usually higher due to the more complex sealing process and the need for more precise machinery to ensure accurate sealing on all four sides. The machinery required for 4-Side-Seal-Sachet production is often more expensive to purchase and maintain.

3-Side Seal Sachets can be produced with simpler and less costly equipment. The production process is relatively straightforward, which makes it more accessible for small and medium-sized enterprises or for short production runs.

In conclusion, the choice between 4-Side-Seal-Sachets and 3-Side Seal Sachets depends on various factors such as the nature of the product, the required level of protection, the production volume, and cost considerations. Understanding the differences between these two types of sachets is crucial for packaging designers, manufacturers, and businesses to make an informed decision and optimize their packaging solutions.