• Seek ways to minimize—and document—your products’ energy consumption in anticipation of likely future customer requirements.

• Use a recognized methodology to document your machinery’s sustainability attributes, such as Total Cost of Ownership, Life Cycle Assessment, or Overall Equipment Effectiveness.

• Benchmark your products and services relative to the Sustainable Packaging Coalition’s definition of sustainability, an informal but widely recognized packaging industry benchmark.

• Form strategic relationships, as appropriate, with converters or other suppliers of packaging, ancillary products, machinery, or automation.

• Design for sustainability, including some or all of the following:

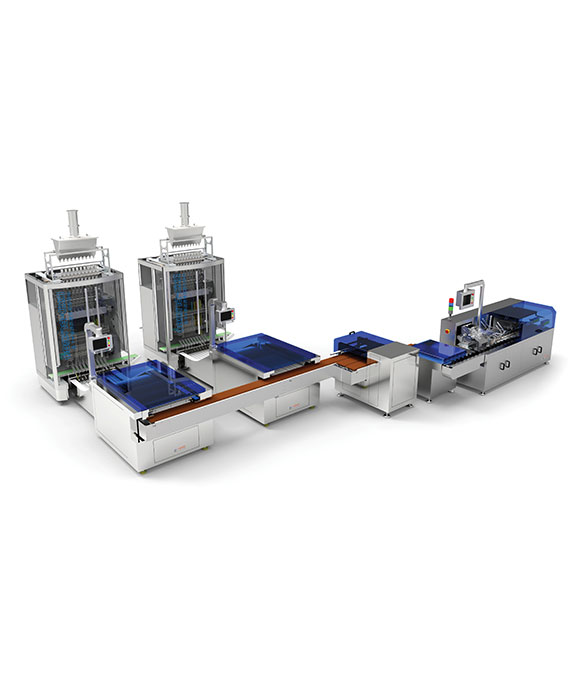

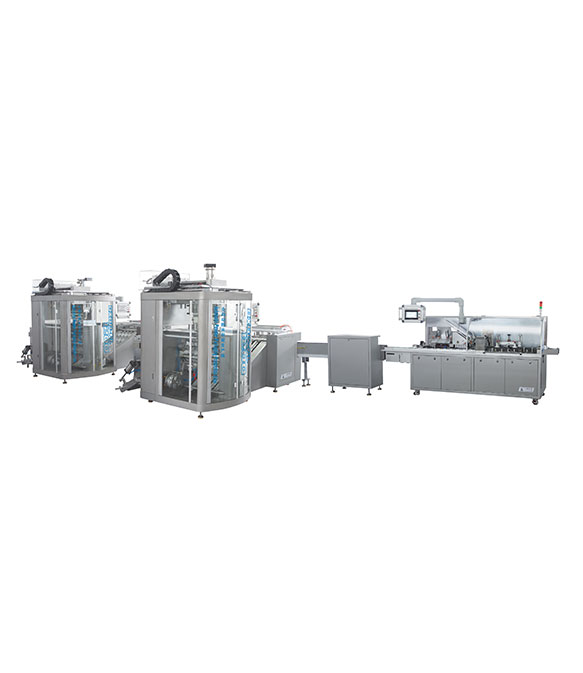

- Disassembly of machinery, to provide customer with greater line layout flexibility and to aid in end-of-life remanufacturing or recovery, including parts and components.

- Reduction or elimination of empty container transport—for example, locating of bottle forming equipment closer to or in the same facility as filling lines to eliminate shipping empty bottles by truck.