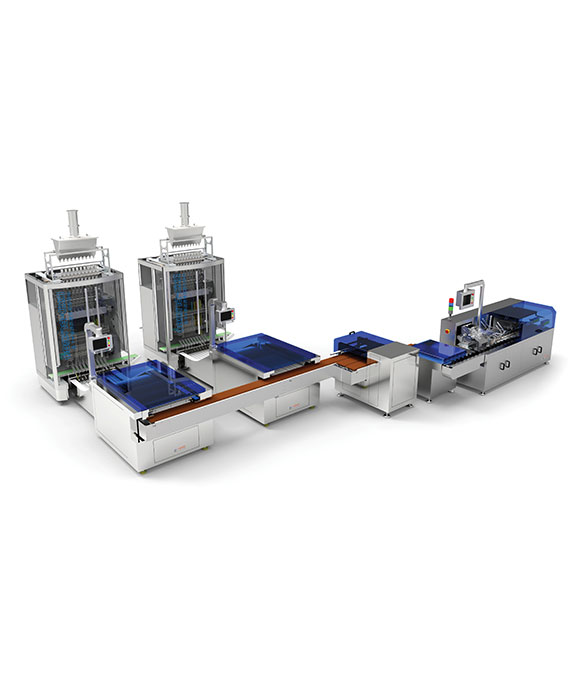

In manufacturing, high - speed granule packing production lines are vital for efficient product packaging. The number of operators needed depends on multiple factors.

Automation Level

Automation is key. In highly automated lines, like in some advanced pharmaceutical or food - processing plants with robotic systems and automated controls, operator needs are minimal. For example, in a German - equipped pharmaceutical firm, the process from raw material to packaged product is largely automated. Here, one operator monitors the system via a control panel, watching parameters such as filling weights and material flow. Another stands by for any sudden issues like minor jams.

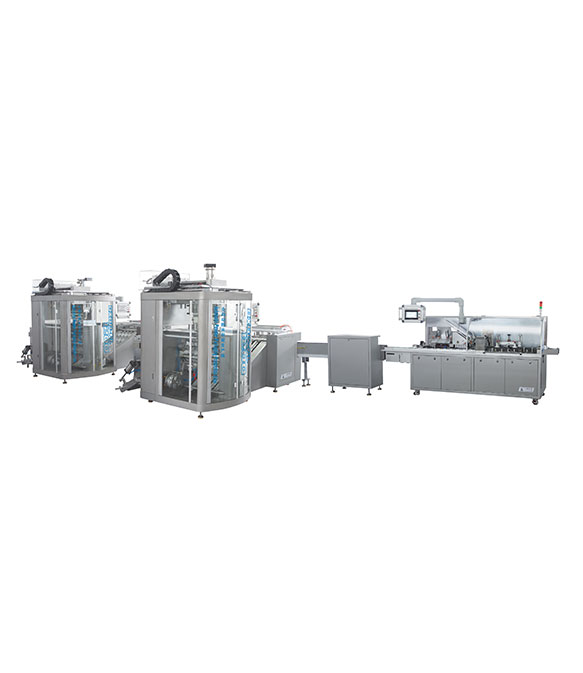

Semi - automated lines require more hands - on labor. A medium - sized food - packaging company might have automated filling but manual sealing and labeling. One operator loads empty packages, another seals them, and a third labels. An additional operator ensures smooth production flow.

Production Process Complexity

Complex production processes demand more operators. A chemical plant blending different granules before packaging needs extra hands for measuring, adding granules, and operating the blender. Once blended, regular packing - line operators take over.

When handling granules with diverse characteristics, skilled operators are essential. In a nuts - and - grains packaging facility, operators must adjust machinery settings for different - sized and - weighted products, increasing the operator count.

Specific Tasks

Tasks like machine setup, maintenance, and quality control also impact operator numbers. A skilled technician sets up the machine before production, adjusting filling volume, sealing temperature, etc. A maintenance operator cleans, lubricates, and repairs during breaks. Quality - control operators check package weight, seal integrity, and labeling. Even with automated quality - control systems, human operators verify results and handle rejects.

In conclusion, the number of operators for a high - speed granule packing production line varies. Highly automated lines may need just one or two operators, while semi - automated or complex ones can require three to a dozen or more. Assessing automation, process complexity, and task requirements is crucial to determine the optimal operator count.