Granular packaging machines generally have two kinds of measurement methods. The following is a simple analysis by the company.

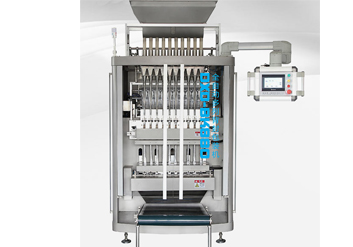

The first measurement method of the granule packing machine: volume-adjustable dynamic metering. This solution uses a stepper motor as the driving component to directly drive the auger to measure the packaged particulate material. The measurement error that is dynamically detected by the electronic scale during the blanking. Feedback to the computer system reflects the dynamic adjustment of the automatic measurement error in the product packaging and achieves higher measurement accuracy of the commodity.

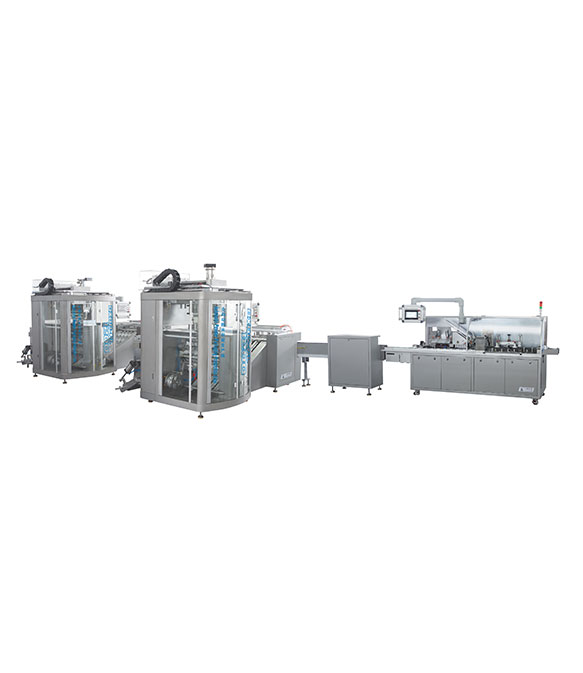

The second metering method of the granule packing machine: constant volume metering. Can only be applied to a certain measurement of a single variety of packaging. Due to the manufacturing error of the measuring cup and the drum, and the change of the material density, the measurement error cannot be adjusted.