Granulated sugar is a staple in most households and is widely used in baking, cooking, and beverage preparation. But have you ever wondered if it can go bad?

Under normal storage conditions, granulated sugar has an extremely long shelf life. It is a highly stable product due to its low moisture content and chemical composition. When stored in a cool, dry place in an airtight container, it can last for years without significant deterioration. This is because sugar crystals are relatively inert and do not readily support the growth of bacteria, mold, or other microorganisms.

However, certain factors can affect the quality of granulated sugar over time. If it is exposed to moisture, it can start to clump together. This doesn't necessarily mean it has gone bad, but it can make it more difficult to measure and use. In some cases, if the sugar has been stored in a damp environment for an extended period, it may even develop a hard crust on the surface.

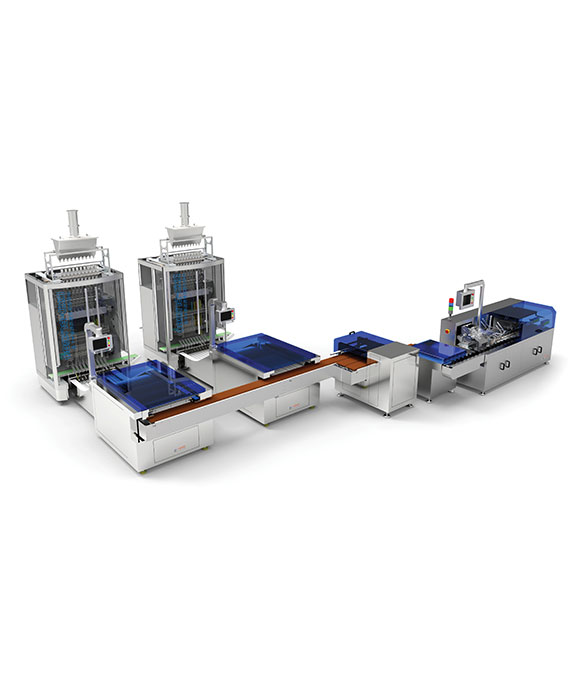

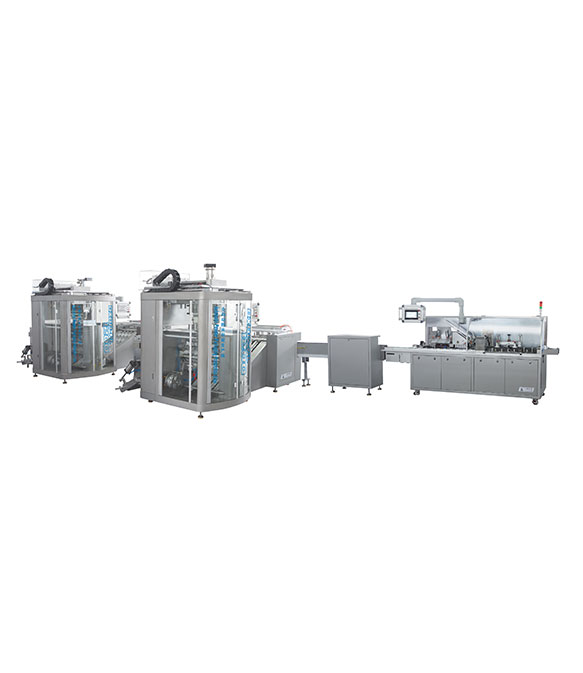

Now, let's consider the role of the Sugar Granule Packing Machine in maintaining the quality of granulated sugar.

Q: How does a Sugar Granule Packing Machine ensure the freshness of granulated sugar?

A: A Sugar Granule Packing Machine is designed to package the sugar in a way that minimizes its exposure to air and moisture. It uses airtight packaging materials and precise sealing mechanisms. The machine fills the bags or containers with a specific amount of sugar, and then seals them tightly, preventing any external air or moisture from entering. This helps to preserve the dry, granular state of the sugar and maintain its quality for a longer period.

Q: What are the key features of a reliable Sugar Granule Packing Machine?

A: A good Sugar Granule Packing Machine should have accurate weighing and filling capabilities to ensure consistent package weights. It should also be able to handle the granular nature of sugar without causing damage to the crystals. The machine should be easy to clean and maintain to prevent any sugar buildup that could affect its performance. Additionally, it may have features like adjustable filling speeds and the ability to handle different package sizes, allowing for flexibility in production to meet market demands.

Q: How has the design of Sugar Granule Packing Machines evolved to better protect granulated sugar?

A: In recent years, there have been advancements in the design of these machines. For example, some modern machines use vacuum packaging technology to further remove air from the package, reducing the risk of oxidation and moisture absorption. Others have improved sealing techniques to create a more reliable and long-lasting seal. These innovations not only help to keep the sugar fresh but also enhance the overall appearance and marketability of the packaged product.

In conclusion, while granulated sugar is a relatively stable product and doesn't go bad easily, proper storage and packaging are essential to maintain its quality. The Sugar Granule Packing Machine plays a crucial role in this process by providing airtight and precise packaging, ensuring that the sugar we use in our daily lives remains in the best possible condition for as long as possible.